Oljekylare Pro line Setrab

Trendab - Skandinaviens Generalagent för Setrab

Trendab var Setrabs allra första kund och har sedan starten varit en stark partner till Setrab. Idag är vi stolta generalagenter för hela Skandinavien och erbjuder Setrabs marknadsledande kylare till motorsport, industri och fordonsapplikationer.

Setrab - Världsledande inom kylteknik

Setrab är marknadsledande inom högpresterande värmeväxlare och levererar produkter till vinnande team i motorsportvärlden. Våra kylare används i de största och mest prestigefyllda racingserierna såsom IndyCar, WRC och FIA GT-serierna. Med expertis från den högpresterande OEM-bilindustrin erbjuder Setrab pålitliga, högpresterande och effektiva kylare för professionell racing och industriella applikationer.

Setrab Proline Eftermarknadsprodukter

Setrab erbjuder tre typer av standardkylarprodukter som är tillgängliga globalt i flera prestanda- och storleksalternativ. Våra kylare är kända för sin kvalitet, hållbarhet och överlägsna kylkapacitet.

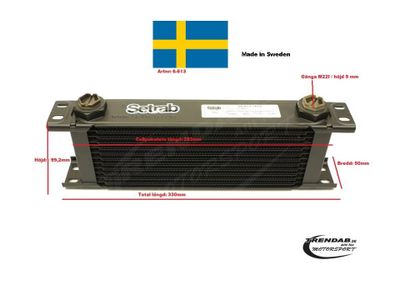

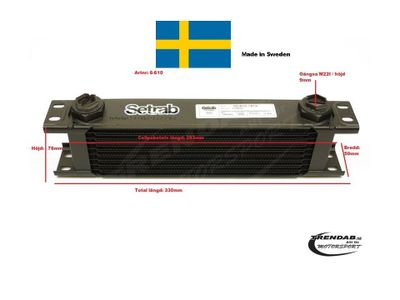

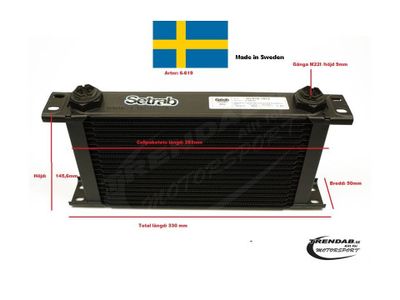

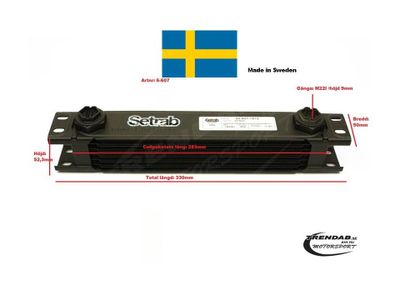

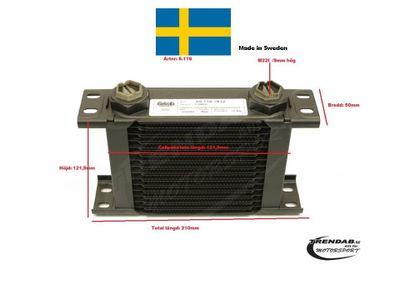

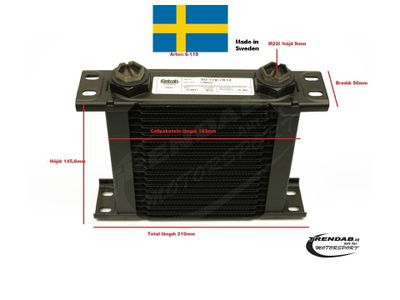

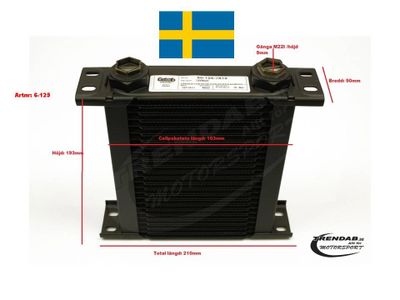

Setrab STD Oljekylare – Svensktillverkad Kvalitet

Setrabs STD-kylarserie tillverkas i Sverige och är konstruerad för att klara upp till 10 bars arbetstryck. Dessa högkvalitativa oljekylare är tillverkade i aluminium med Nocolok-lödprocess och lackerade med epoxilack för maximal korrosionsbeständighet.

Användningsområden:

Motorsport

Hydrauliska system

Transmissioner

Transformatorer

Bränslekylning

Dimensioner och Modeller

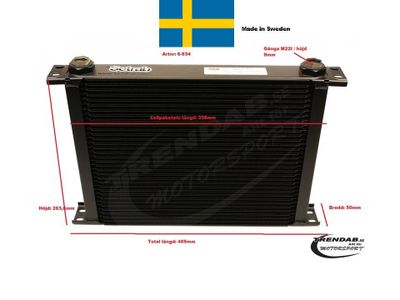

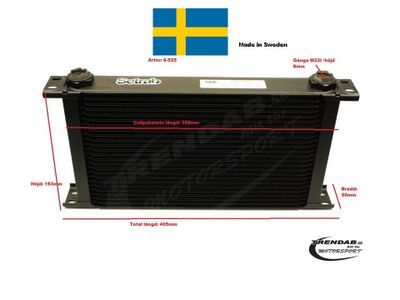

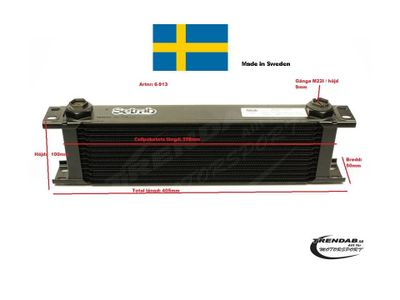

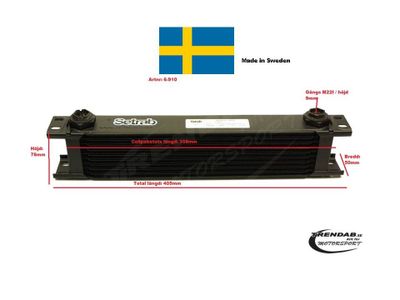

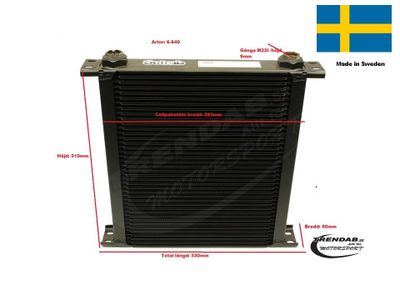

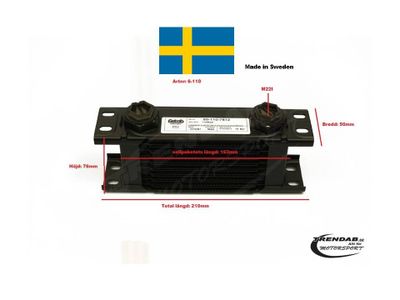

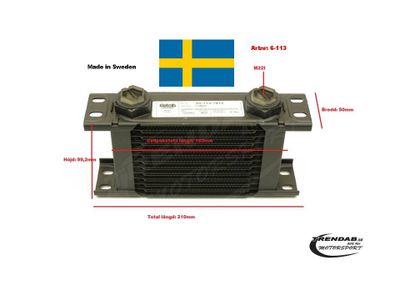

STD-kylaren finns i tre serier, var och en i flera olika höjder:

1-serien: Totalbredd 210 mm, cellpaket 163 mm, tjocklek 50 mm

6-serien: Totalbredd 330 mm, cellpaket 283 mm, tjocklek 50 mm

9-serien: Totalbredd 405 mm, cellpaket 385 mm, tjocklek 50 mm

Viktigt att tänka på vid montering

För att maximera livslängd och prestanda bör kylaren monteras vibrationsfritt, så att den kan utvidga sig naturligt vid uppvärmning. En stum montering kan leda till skador och försämrad funktion.

Tekniska Specifikationer

Arbetstryck: 0-10 bar(g) dynamiskt

Tryckpulsationers uthållighet: 200 000 pulsationer, 0-10 bar(g), 2 Hz, 60°C oljetemp

Maxtryck: 12 bar(g)

Bräcktryck: 37 bar(g)

Trycktest: 10 bar(g)

Läckagetest: 4 bar(g)

Arbetstemperatur: -40°C till 150°C

Korrosionsbeständighet: 20 dagar enligt SWAAT G85-94 A3

Inre renhet: ISO 4406 16/14

Generella dimensionstoleranser: ISO 2768-v

Material: Aluminiumlegeringar

Maximalt åtdragningsmoment för anslutningar: 40 Nm

Beställ din Setrab kylare idag

Vi erbjuder expertis och marknadsledande kylteknik för motorsport och industri. Kontakta oss för mer information, tekniska specifikationer och prislistor.