16 bar Setrab Heavy duty oil coolers/Oljekylare

Setrab ProLine COM Oljekylare – Högpresterande Oljekylare för Krävande Applikationer

Läs mer

Liknande produkter

Beskrivning av 16 bar Setrab Heavy duty oil coolers/Oljekylare

Setrab ProLine COM Oljekylare – Högpresterande Oljekylare för Krävande Applikationer

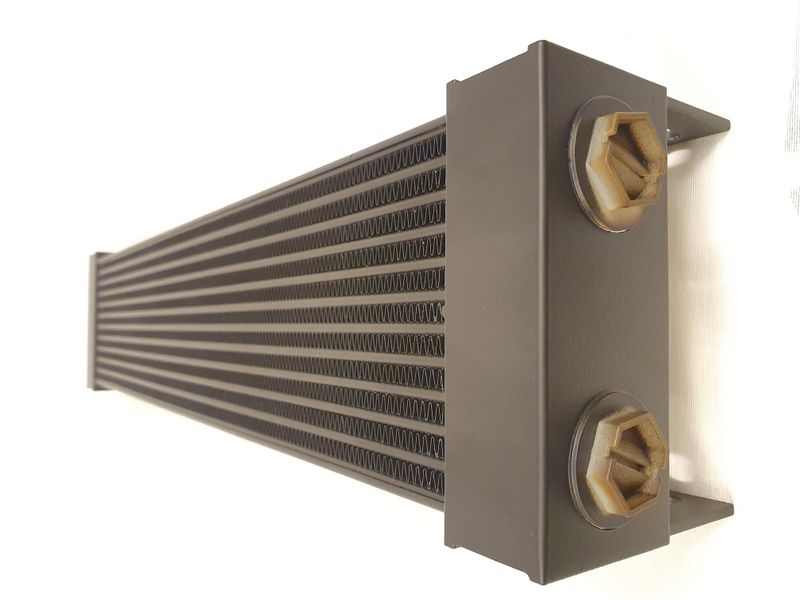

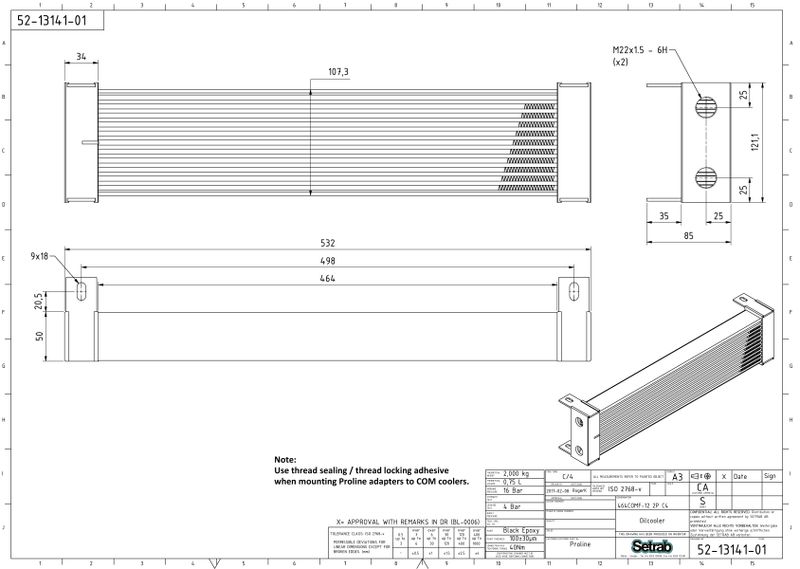

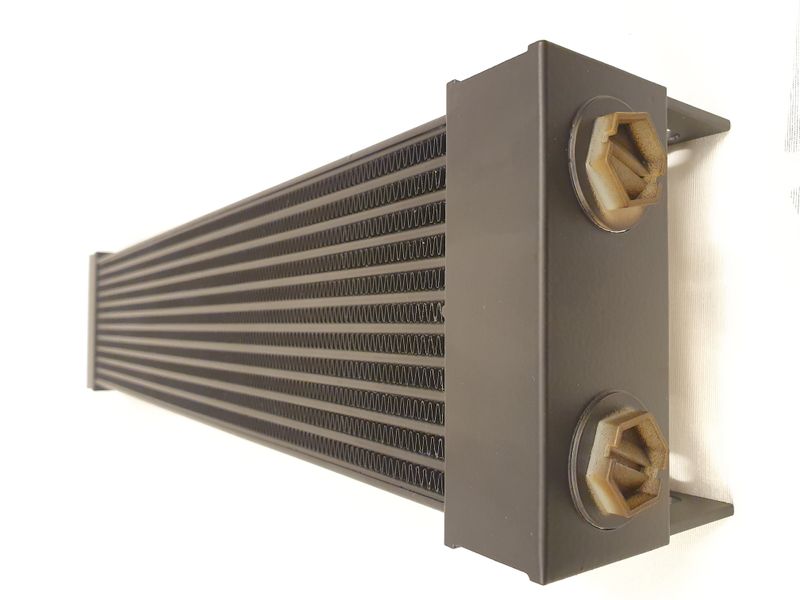

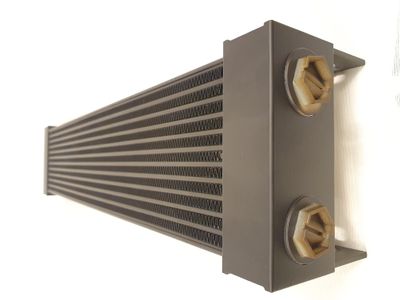

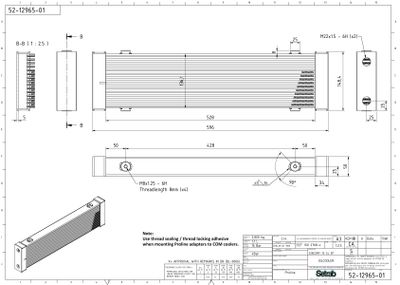

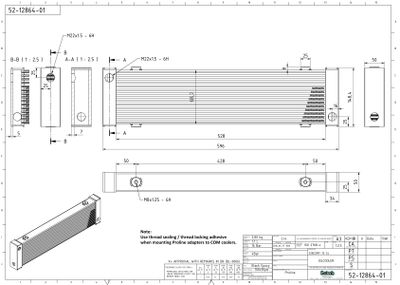

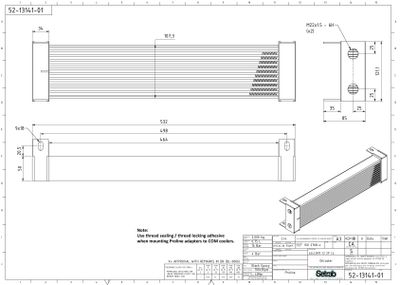

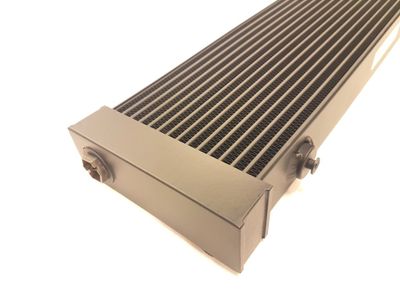

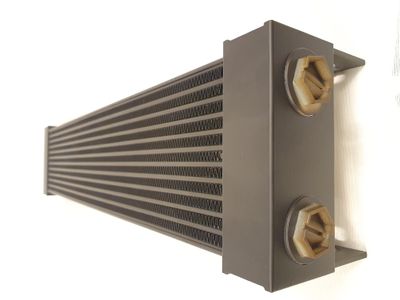

Setrab ProLine COM Oljekylare är den senaste innovationen inom oljekylning, utvecklad för att möta de mest krävande applikationerna. Designad för att hantera högre tryck (16 bar) och vibrationer, är denna oljekylare den perfekta lösningen för motorsport, ökenrally, hydrauliska system och andra tunga applikationer.

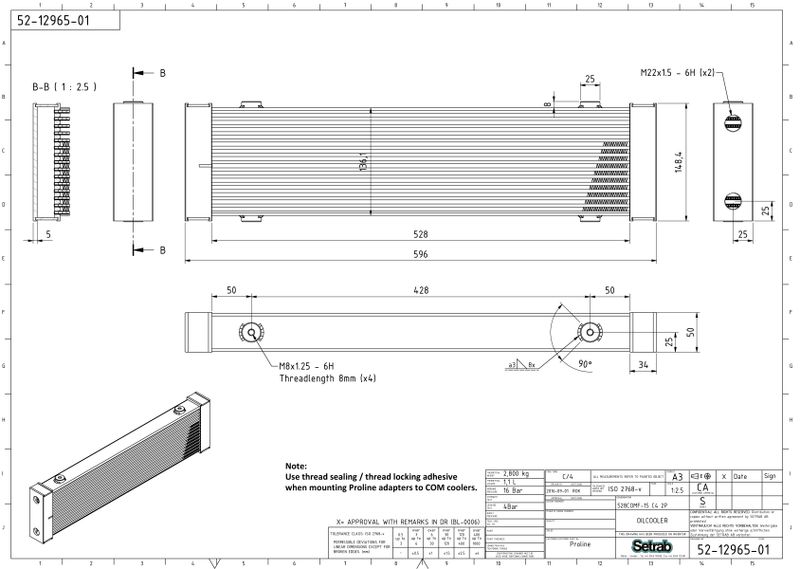

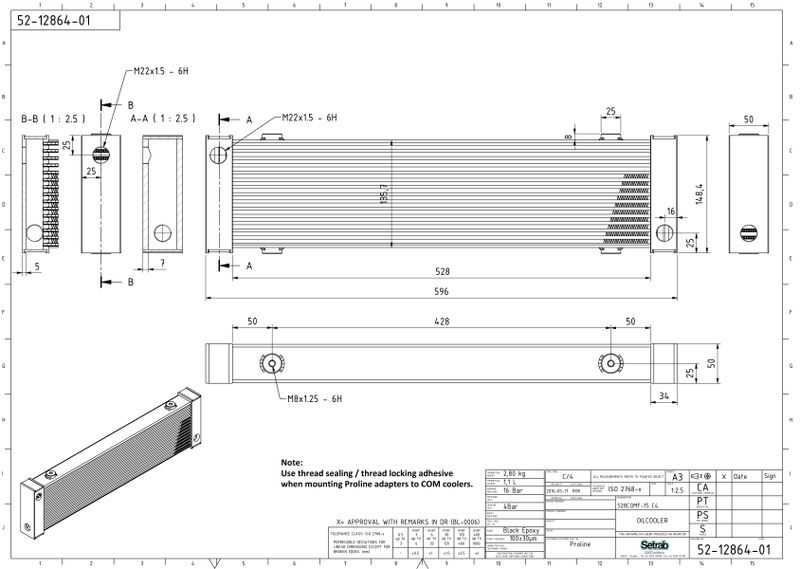

Tekniska Specifikationer:

- Arbetstryck: 0-16 bar(g) dynamiskt

- Maximalt Tryck: 25 bar(g)

- Explosionstryck: 50 bar(g)

- Trycktest: 10 bar(g)

- Läcktest: 4 bar(g)

- Arbetstemperatur: -40°C till 150°C

- Korrosionsbeständighet: Tål 20 dagars saltvattenexponering (enligt SWAAT G85-94 A3)

- Inre Renlighet: ISO 4406 16/14

- Maximalt Åtdragningsmoment för Anslutning: 40 Nm

- Material: Aluminiumlegeringar av hög kvalitet

Fördelar med Setrab ProLine COM Oljekylare:

- Hög Tryckkapacitet: Klarar upp till 16 bar arbetstryck och 50 bar explosionstryck, vilket gör den idealisk för extrema förhållanden som i motorsport och industriella applikationer.

- Vibrationsbeständig: Byggd för att tåla vibrationer och påfrestningar, vilket ger långvarig prestanda under tuffa förhållanden.

- Korrosionsbeständig: Har utmärkt korrosionsmotstånd och tål 20 dagars saltvattenexponering, vilket förlänger kylsystemets livslängd.

- Hög Flödeskapacitet: Effektiv kylning för att hantera stora mängder vätska och bibehålla stabil prestanda under höga temperaturer.

Perfekt för Motorsports och Industriella Applikationer

Setrab ProLine COM Oljekylare är det bästa valet för motorsport, ökenrally och hydrauliska system som kräver en pålitlig och hållbar oljekylare. Denna oljekylare är designad för att ge överlägsen prestanda även under de mest extrema förhållandena.

Beställ Setrab ProLine COM Oljekylare idag!

För att säkerställa optimal prestanda och långvarig hållbarhet i ditt kylsystem, välj Setrab ProLine COM Oljekylare. Med sin robusta konstruktion, höga tryckkapacitet och vibrationsdämpande egenskaper är den en investering för framtiden. Klicka på "Lägg i kundvagn" för att beställa och förbättra ditt kylsystem!