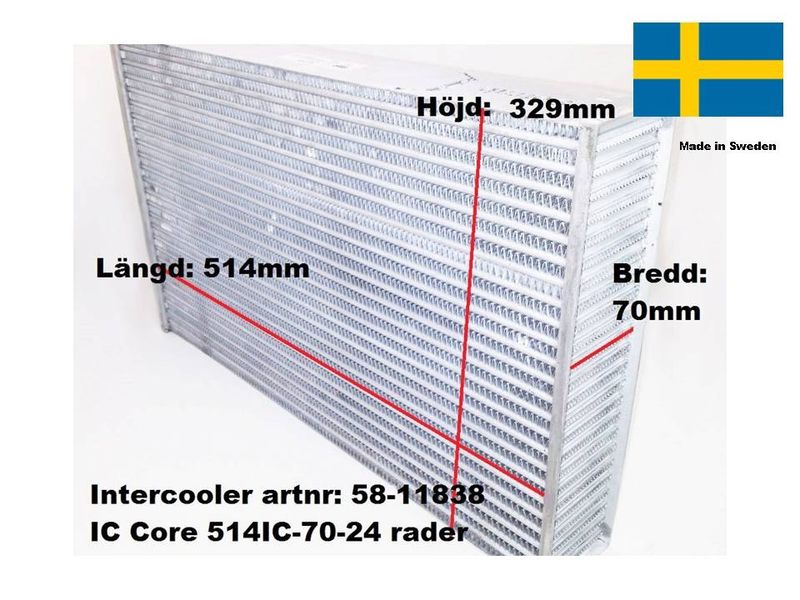

58-11838 IC Core 514IC-70-24 rader

Setrab svensk tillverkad intercooler i extremt hög kvalitet. En intercooler att lita på.

Alla intercoolers är 100 % läckage testade från fabrik. Intercoolern säljs utan gavlar (endast cellpaketet med ram)

Storlek: L: 514mm B:70mm H: 329mm (alla angivna mått gäller cellpaketet, ramen på gavlarna är ej inräknad)

Läs mer

Liknande produkter

Beskrivning av 58-11838 IC Core 514IC-70-24 rader

Working Pressure: 0-2,5 bar(g) dynamic

The range in which the cooler is designed to operate (above atmospheric pressure). The word "dynamic" implies that the pressure can fluctuate between the limits.

Pressure Pulsation Endurance: 100k pulsations, 0-3 bar(g), 0.5-1Hz, 200 C air temp

How many times the cooler can withstand pressurizaton between a lower and an upper limit. The Herz number indicates the frequency of pulsations per second.

Max Pressure: 4 bar(g)

The maximum operating pressure.

Burst Pressure: 6 bar(g)

The maximum pressure the cooler can withstand before bursting.

Leak test: 1.5 bar(g) (core)

The pressure level the cooler is tested at for leaks after the pressure test.

Working Temperature: -40 C to 220 C

The temperature range the cooler is designed to operate within. Operating temperatures outside of the defined range will negatively affect the strength and durability of the cooler.

Corrosion Endurance: 20 days SWAAT G85-94 A3 960h ISO 9227 NSS

How long the cooler can withstand a salt spray test before starting to leak. The test simulates the expected lifetime exposure of a typical vehicle to a mixture of water and road salts.

Inner Cleanliness: ISO 16232:10, CCC=V(B-K21/C-K18/F-K12/I-K3/J-K00), <10mg impuriteies total

The maximum amount of particles the cooler is expected to contain.

General Dimensional Tolerances: ISO 2768-v

The standard to which the cooler conforms regarding dimensions specified on the technical drawing.

Material

The material the cooler is made of: Aluminium alloys